For years, biodegradable plastics were marketed as the eco-friendly answer to pollution, but they often failed to live up to the promise. By 2025, that story is changing as next-gen biodegradable plastics finally deliver on true sustainability.

Many biodegradable plastics didn’t break down properly, required industrial composting, or replaced one environmental issue with another. However, a wave of new materials and manufacturing breakthroughs is now finally bringing biodegradable plastics closer to true sustainability.

These innovations aren’t just cosmetic fixes. They represent a fundamental reevaluation of how we produce, utilize, and dispose of one of the most pervasive materials on Earth.

The Problem with “Old” Bioplastics

Early biodegradable plastics, such as polylactic acid (PLA), sounded like a miracle. They were derived from renewable sources, such as corn or sugarcane, and are capable of decomposing over time. But in reality, many required tightly controlled industrial composting conditions to break down, meaning they persisted in landfills much like conventional plastics.

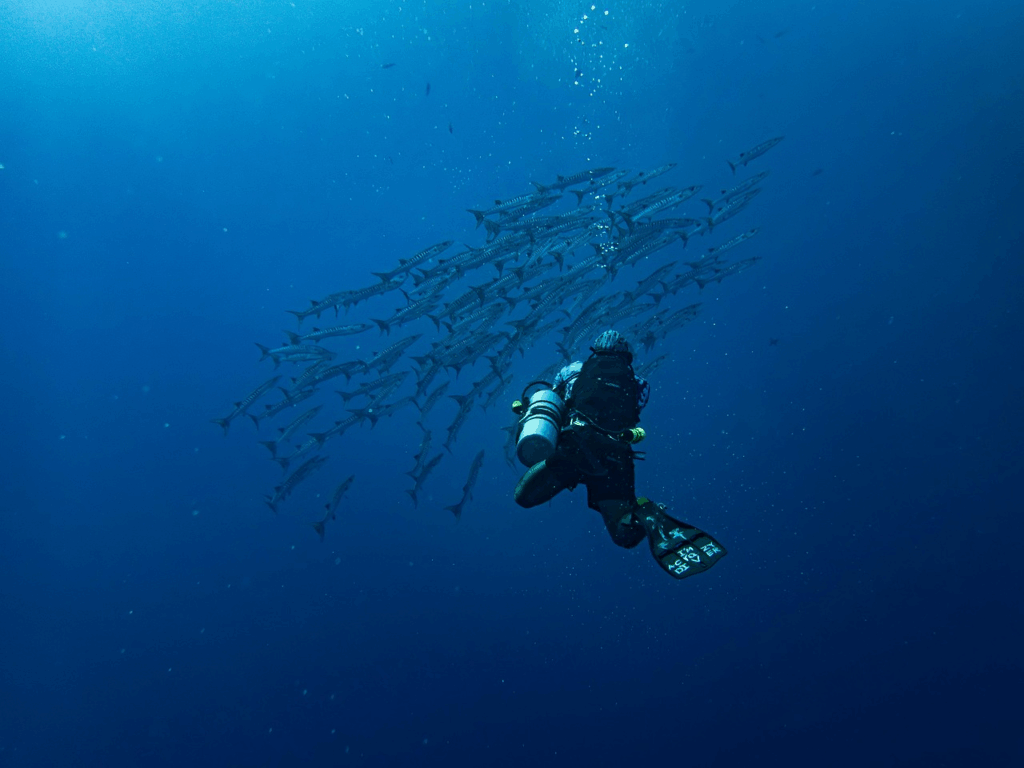

Others, labeled as “oxo-degradable,” break down into microplastics under sunlight and oxygen exposure, rather than fully decomposing, and pollute soil and waterways. As consumers became more informed, skepticism toward greenwashing grew.

The result: biodegradable plastics needed a complete redesign, not just in composition, but in lifecycle thinking.

See How Climate Innovations Are Powering the Green Economy for the bigger picture.

The New Science of Smart Decomposition

The latest generation of biodegradable plastics is living up to its name. Scientists are developing polymers that break down under real-world conditions, whether in soil, seawater, or home compost bins. These new materials use enzymatically active polymers, which are plastics embedded with catalysts that trigger controlled degradation when exposed to natural microbes or moisture.

For example, researchers at the University of California, Berkeley, have developed a self-destructing plastic that begins to decompose within days when placed in water or compost. Similarly, startups like Biolo and RWDC Industries are producing materials that degrade into harmless organic matter, leaving no microplastic residue.

Even traditional plastic producers are getting involved. Companies like BASF and Danimer Scientific are blending biodegradable additives into standard polymers to accelerate breakdown without compromising durability during use.

Turning Waste into Resource

The most significant shift isn’t just in chemistry; it’s in mindset. The new model treats waste as a resource. PHA (polyhydroxyalkanoate) plastics, for instance, are made by feeding plant oils or food waste to microbes, which produce natural polymers inside their cells. After harvesting, these polymers are turned into packaging that later decomposes in soil or ocean environments.

This “bio-loop” approach not only reduces waste but also lessens dependence on fossil fuels. When managed correctly, biodegradable plastics can even become carbon-neutral, returning carbon to the soil rather than releasing it into the atmosphere.

To complete the cycle, major cities are expanding composting infrastructure and labeling standards to ensure these materials end up in the right waste streams. Collaboration between governments, manufacturers, and consumers is finally closing the loop that earlier generations ignored.

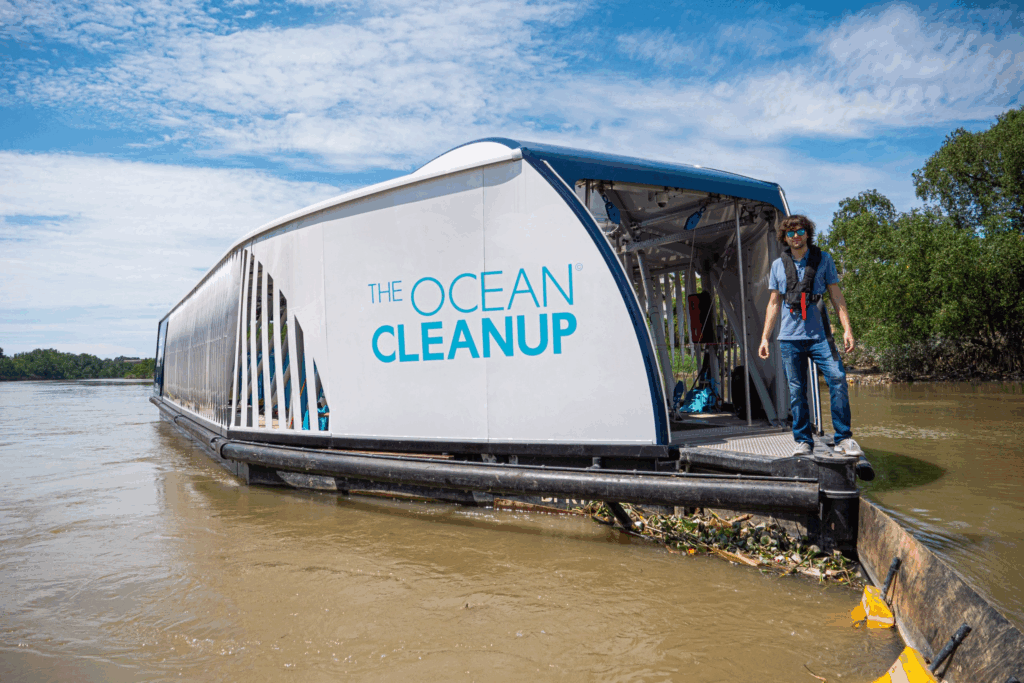

Read Meet the Robots Cleaning Our Oceans for large-scale cleanup technology.

Industries Leading the Change

The food packaging and fashion industries are leading the charge. Restaurants and grocery brands are switching to home-compostable alternatives for their petroleum-based wrappers. Shoe and apparel companies are experimenting with plant-based fibers and biopolymer soles designed to decompose safely when discarded.

Even e-commerce giants are adopting biodegradable shipping materials to reduce their massive packaging footprints. Meanwhile, the medical field, traditionally reliant on single-use plastics, is investing in bioplastics for surgical tools, sutures, and temporary implants that safely dissolve in the body.

Curious how better storage and materials science connect? Check Inside the Next Frontier of Battery Technology.

The Future of Plastic — and the Planet

While biodegradable plastics aren’t a silver bullet, they’re a decisive step toward a circular economy. Experts caution that proper waste management remains crucial. Even the best bioplastics won’t decompose if trapped in oxygen-deprived landfills. However, combined with improved recycling systems and more innovative design, these new materials could significantly reduce plastic pollution.

The next generation of plastics is teaching us a simple truth: sustainability doesn’t mean giving up convenience; it means engineering it responsibly. If the innovations of 2025 are any indication, the world may finally have a version of plastic that works for the planet, rather than against it.