For years, the global microchip shortage has disrupted industries ranging from smartphones to automobiles, highlighting the extent to which modern life relies on tiny semiconductors. However, by 2025, the crisis had finally eased. In this post-microchip shortage era, new factories have stabilized supply chains and restored balance, sparking a new period of innovation.

With production back on track, tech companies are asking a different question: now that we’ve fixed the shortage, how do we future-proof against the next one? The answer lies not just in making more chips, but in creating smarter, more sustainable, and more specialized ones.

How the Shortage Finally Ended

The shortage began in 2020, when pandemic disruptions coincided with a surge in demand for electronics. Supply bottlenecks rippled across global industries, halting car production and delaying everything from gaming consoles to washing machines. By 2023, governments and corporations realized the semiconductor supply chain was too fragile and too concentrated in a few regions.

In response, the U.S., Europe, and Asia poured billions into domestic chip manufacturing. America’s CHIPS and Science Act, the EU’s Chips for Europe Initiative, and major expansions by companies like TSMC, Intel, and Samsung diversified production and reduced reliance on single suppliers.

By 2025, those investments paid off. New fabs (fabrication plants) are running at capacity, and global chip inventories have finally caught up with demand.

See Inside the Next Frontier of Battery Technology to understand the energy breakthroughs powering fabs and edge devices.

A Shift Toward Regional Resilience

Instead of depending on one or two nations for the world’s chips, production is becoming more distributed. North America now leads in advanced processor design, Europe focuses on automotive and industrial chips, and Asia remains strong in high-volume manufacturing.

This regional specialization has created a more resilient ecosystem. If one region experiences a disruption, others can compensate for it. It’s also spurred healthy competition and collaboration among global tech hubs.

Companies are adopting “just-in-case” supply strategies, maintaining larger inventories rather than razor-thin margins. The lesson learned: efficiency without redundancy is a recipe for disaster.

The Rise of Specialized and Sustainable Chips

The end of the shortage isn’t just about restoring supply; it’s redefining demand. As artificial intelligence, autonomous vehicles, and Internet of Things (IoT) devices evolve, the world needs chips optimized for specific tasks rather than one-size-fits-all processors.

AI accelerators, neuromorphic chips, and quantum-ready semiconductors are now at the forefront of research. These chips mimic human neural pathways or perform quantum calculations, enabling faster and more energy-efficient computing.

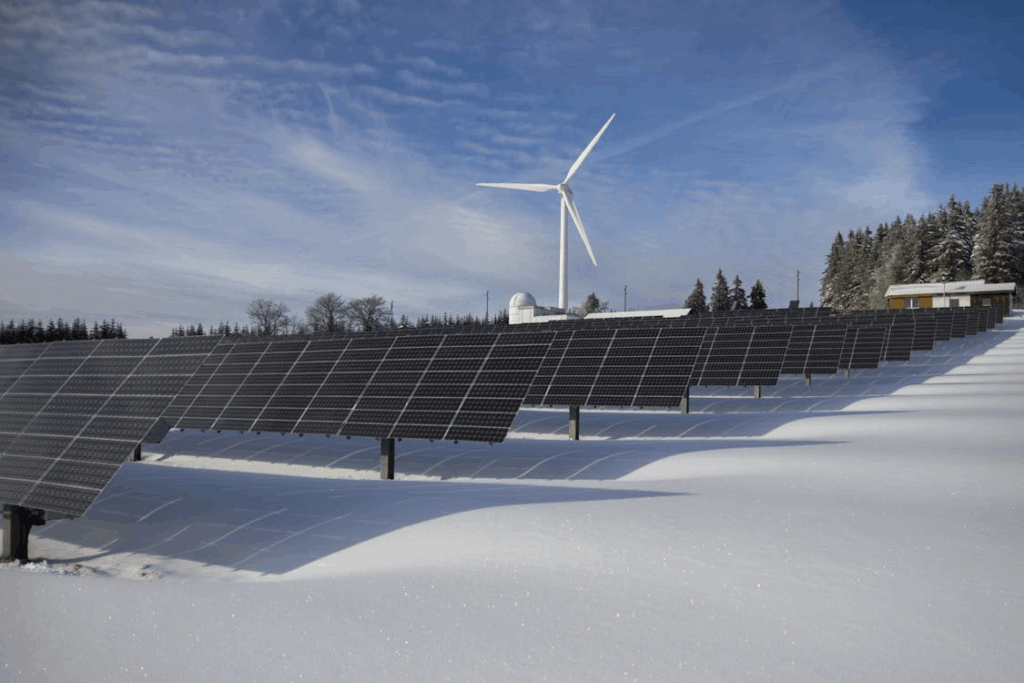

Sustainability is also becoming a priority. Semiconductor fabrication has traditionally been water- and energy-intensive; however, new plants are adopting green technologies, including closed-loop water recycling, renewable-powered fabs, and biodegradable materials for packaging. Some companies are even experimenting with carbon-neutral chips, offsetting emissions from production.

Check out The Race to Build the First Quantum Internet to see why these networks will demand new designs.

Lessons for the Next Crisis

The microchip shortage revealed that technology is only as strong as its weakest link in supply. Future preparedness will depend on better forecasting, flexible design, and material diversification.

For example, researchers are developing graphene-based and organic semiconductors as potential alternatives to silicon. These materials could be manufactured at lower temperatures and used in flexible or wearable electronics. Meanwhile, 3D chip stacking, a method of layering components vertically instead of horizontally, increases performance without expanding footprint, making devices faster and smaller.

Cybersecurity has also become integral to the design of chips. With hardware-based attacks on the rise, manufacturers are embedding encryption and tamper detection directly into processors, making future devices more secure at the silicon level.

Read What Makes a City ‘Livable’ in 2025? to explore how fab investments, transit, and green grids shape regions.

A Stronger, Smarter Tech Landscape

The post-microchip shortage era marks a turning point for global technology. Instead of taking semiconductors for granted, industries now view them as strategic assets, equally as vital as oil or energy. Governments are prioritizing chip independence not only for economic reasons but also for national security.

For consumers, this new stability means faster innovation cycles and fewer shortages of the gadgets that power daily life. For the planet, it’s an opportunity to align technology’s growth with sustainability.

The microchip crisis revealed vulnerabilities, but it also inspired reinvention. The world didn’t just fix the shortage; it built a stronger foundation for the technologies that will define the next decade.